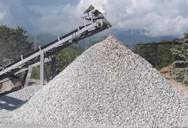

Installation De Lavage Dor De Coree POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- Acheteurs De Plantes Concasseur Saoudiennes Usine De Concasseur

- Entreprises De Matériel De Fabrication De Briques En Allemagne

- clermont concasseur entierement mobile

- equipements de pompage du sable

- industrie du concasseur de marbre

- mills rouleau vertical prix de concasseur

- processus de broyage dans le charbon

- pilule prix de concasseurs au kenya

- Matériel De Construction De Marteaux De Broyeur Indonésie Marteaux

- ligne artificielle en pierre de quartz

- le carbonate de calcium de broyage Péroupedia

- comment gérer les résidus de déchets dans la construction

- concasseur de pierre plante

- mesin methodes de broyage de ciment diagramme

- coût pierre concasseur Indonésie oman

pierre usine de concassage à gulbarga karnataka

petit fournisseur Indonésie l''échelle des prix de concassage de pierre

2024.7.17

Concasseur de pierres Indonésie - Broyage de galets, 2024.7.10 AIMIX propose un concasseur de pierres en Indonésie pour le traitement des roches, des cailloux et Read More

Concasseur de pierres Indonésie - Broyage de galets, 2024.7.10 AIMIX propose un concasseur de pierres en Indonésie pour le traitement des roches, des cailloux et Read More

Concasseur de pierres Indonésie - Broyage de galets,

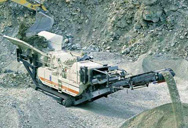

2024.10.29 AIMIX propose un concasseur de pierres en Indonésie pour le traitement des roches, des cailloux et du calcaire, et d'autre part pour l'exploitation minière, la fusion, les

Read More

Pierre Usine De Concasseur En Indonesie - prospexion

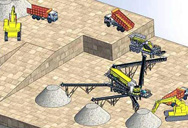

2024.3.7 Une usine de concasseur de pierres en Indonésie comprend généralement un concasseur à mâchoires, un concasseur à cône, un concasseur à percussion, un alimentateur

Read More

liste des producteurs de concasseurs de pierres indonésie

2024.2.14 Concasseur de pierres Indonésie - Broyage de galets, 2024.7.10 Concasseur de pierres Indonésie - Broyage de galets, basalte, pavés. AIMIX propose un concasseur de

Read More

Prix abordable de l'usine de concassage de pierre pour une

2024.11.11 Trouvez le meilleur prix de l'usine de concassage de pierre et la solution de concassage adaptée à vos besoins à partir de AIMIX. Augmentez votre productivité et

Read More

équipements pierre concasseur indonésie

pierre concasseur Indonésie machoires POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE. ... Notre gamme d’équipements et de services pour l'exploitation minière et

Read More

fabricant de concasseur de pierres indonésie - capitalgraphic

fournisseurs de concasseurs de pierres en indonésie. Les capacités du concasseur de pierres en Indonésie vont de 1 à 1000 tonnes, pour votre projet, nous vous fournirons plus de deux

Read More

calcul du coût de production concasseur de pierres indonésie

Concasseur de pierres Indonésie. AIMIX propose un concasseur de pierres en Indonésie pour le traitement des roches, des cailloux et du calcaire, et d'autre part pour l'exploitation minière, la

Read More

coût pierre concasseur Indonésie oman - iiidesign

Concasseur de pierres Indonésie - Broyage de galets, 2024.7.10 AIMIX propose un concasseur de pierres en Indonésie pour le traitement des roches, des cailloux et du calcaire, Read More

Concasseur de pierres Indonésie - Broyage de galets, 2024.7.10 AIMIX propose un concasseur de pierres en Indonésie pour le traitement des roches, des cailloux et du calcaire, Read More

coût de 200thp concasseur Indonésie calcaire - prospexion

2024.7.14

Concasseur de pierres Indonésie - Broyage de galets, 2024.7.10 AIMIX propose un concasseur de pierres en Indonésie pour le traitement des roches, des cailloux et Read More

Concasseur de pierres Indonésie - Broyage de galets, 2024.7.10 AIMIX propose un concasseur de pierres en Indonésie pour le traitement des roches, des cailloux et Read More

prix groupe electrogene au Mali

2023.8.29 Achat du prix groupe electrogene au Mali. Achat du prix groupe electrogene au Mali, Les groupes électrogènes fonctionnent généralement avec des combustibles tels que le diesel, l’essence ou le gaz. Les variations des

Read More

Démarrer une entreprise de fabrication de

2023.1.25 3. Déterminer le coût. Avant de démarrer une entreprise, vous devez déterminer si vous disposez d’un capital suffisant pour couvrir les frais d’établissement. Vous devez tenir compte du coût d’achat ou de location du

Read More

coût de la pierre concassée par tonne en algérie

\n \n prix de la pierre concassee \n. BOMIX Pierre concassée 1 4 po,30 kg 2022S30 RONA.La pierre concassée est obtenue par le concassage de la pierre calcaire.On peut s'en servir avec du ciment sable pour faire du béton,ou encore comme sous couche pour le drainage et comme assise de finition pour le pavé uni.coût du nouveau projet pour broyeur de pierres en

Read More

Les astuces pour démarrer une entreprise de production de brique

2024.3.15 3. Déterminer le coût. Avant de démarrer une entreprise, vous devez déterminer si vous disposez d’un capital suffisant pour couvrir les frais d’établissement. Vous devez tenir compte du coût d’achat ou de location du site à partir duquel vous fabriquerez les briques.

Read More

Comparaison entre pays: Indonésie / Oman

Oman et Indonésie comparer: Démographie, Économie, Énergie, Langues et autres recoupements. ... Coût de la vie: 56: 64: Popularité: 40: 31: Économie Détails pour Indonésie et Oman Indonésie Oman; Monnaie: Rupiah indonésien (1 IDR = 100 Sen) Rial omani (1 OMR =1000 Baizas) Taux de chômage:

Read More

coût pierre concasseur à oman - pasaz-kaliski

concasseur de pierres oman2020.1.14 Concasseur. Les concasseurs de pierres / roches de la société JXSC comprennent un concasseur à cône, un concasseur à mâchoires, un concasseur à percussion, un concasseur mobile, une machine de

concasseur de pierres oman2020.1.14 Concasseur. Les concasseurs de pierres / roches de la société JXSC comprennent un concasseur à cône, un concasseur à mâchoires, un concasseur à percussion, un concasseur mobile, une machine de  Co ... coût pierre concasseur à oman POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ...Read More

Co ... coût pierre concasseur à oman POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ...Read More

Machine a Brique Prix Cote d'Ivoire - Pondeuseaparpaing

2024.6.17 Voir centrale a beton et concasseur. Obtenir une machine à blocs de béton d’occasion à vendre ou une machine de fabrication d’agglos manuelle OTT6A, cette machine à brique manuelle petite presse manuelle est outillé d’une nouvelle génération de presses plus performantes, manuelles ou mécaniques, hydrauliques ou à compression ...

Read More

Concasseur à cône TG220 - terex

2024.10.30 Concasseur à cône modulaire; Concasseur VSI modulaire; Crible modulaire; Mobile. Concasseur à mâchoires mobile ... concasseurs à cône impressionnants peuvent être facilement et efficacement mis en œuvre pour fournir le meilleur coût par tonne de produits cubiques en sélectionnant une cavité de concassage et une amplitude excentrique ...

Read More

coût du concasseur de pierres à oman - koparki-lublin

Les Concasseur de pierre a vendre sont très populaires aux Africa, en South Americat en Southeast Asia.Concasseur Mechine à Vendre à Oman,adresse de concasseurs de pierre à vendre en oman. Prix Concasseur De Pierre: Concasseur a vendre ou maroc Posté à l'adresse: March 26, 2013. godets concasseurs à . à vendre listes de produit sur ...

Read More

coût de 200thp concasseur Indonésie calcaire - prospexion

2024.7.14 Trouvez facilement votre concasseur pour pierre calcaire parmi les 72 références des plus grandes marques (Liming, Fabo, ROCKSTER, ...) sur DirectIndustry, le spécialiste de . Voir plus; ... coût de 200thp concasseur Indonésie calcaire. Série CS Concasseur 5 1/2 Type de Ft - lagiraudiere. série cs concasseur à cône 5 1 2 pi de type ...

Read More

Concasseur mobile prix en Turquie - concasseur de pierre

2023.3.30 Concasseur mobile prix en Turquie. Vous pouvez trouver des concasseurs mobile prix partout dans le monde plus precisement en Turquie, dans l’asphalte sur lequel vous parcourez partout , dans le béton à partir duquel ont fait de construction.Nous sommes dans ce domaine plus de 10 ans, reconnue ici dans la region de Trabzon plus precisement toute

Read More

Budget et Coût de la Vie pour un Voyage en

2024.6.27 🍽 Coût de la nourriture. Repas dans la rue ou sur un marché, sans boisson : 1 à 6 € (2 € en moyenne) Repas dans un restaurant économique, sans boisson : 1 à 11 € (4 € en moyenne) Bouteille d’eau 1,5 L dans un

Read More

Fer a Beton Togo - Prixdefer Fournisseur

2023.10.5 Prix du Fer à Béton Togo. Le prix du fer à béton Togo actuellement a beaucoup augmenté au cours de l’année 2023. Nous pouvons vous livrer le fer à beton au prix de 695 dollar (prix valable jusqu’au 31 août

Read More

Concasseur pour pierres - Tous les fabricants industriels

Trouvez facilement votre concasseur pour pierres parmi les 152 références des plus grandes marques (Liming, Fabo, CONSTMACH, ...) sur DirectIndustry, le spécialiste de l’industrie pour vos achats professionnels. ... un faible coût d'utilisation, un entretien ... Ajouter au comparateur Retirer du comparateur. concasseur à mâchoire DMJ90 ...

Read More

Coût de la Vie en Indonésie - fr.numbeo

Coût de la Vie en Indonésie . Sélectionnez une ville en Indonésie: Indice; Indice du Coût de la Vie (Excluant le Loyer): 25,35: Indice de Loyer: 8,13: Indice des Courses: 34,31: Indice des Restaurants: 15,69: Indice du Coût de la Vie Plus Loyer: 17,67: Pouvoir d'Achat Local: 33,56: Vivez-vous en Indonésie? Ajouter des données pour l ...

Read More

Les groupes électrogènes en côte d’ivoire

2023.9.20 Ces fonctionnalités peuvent augmenter le coût initial, mais elles offrent des avantages en termes d’efficacité et de facilité d’utilisation. Bien que les coûts initiaux d’installation puissent être élevés, En fonction de la demande actuelle et des contraintes d’approvisionnement, les prix des groupes électrogènes peuvent fluctuer.

Read More

Prix à Oman. Calculateur du coût de la vie et du budget de

Le coût de la location ou de l'achat d'un appartement à Oman varie en fonction de sa localisation. En moyenne, la location d'un appartement avec une chambre et un salon en dehors du centre-ville coûte environ 156 OMR (375 €) par mois, tandis que le même type d'appartement en centre-ville peut coûter environ 212 OMR (511 €) par mois.

Read More

Concasseur de pierre - tous les fournisseurs - Hellopro

Concasseur à mâchoires primaire Zenith - haute performance et faible coût. Vendu par : Shanghai Zenith Mining and Construction Machinery Co,.Ltd. ... CONCASSEUR DE PIERRE : Monsieur , nous avons l'honneur de vous demander l'offre des prix pour une unité complété d'occasion pour production de sable fluvial d'une capacité de 100m3/h ...

Read More

Coût de la vie et prix à Oman Mise à jour juil 2023

2023.7.26 Découvrez le coût de la vie à Oman avec TravelTables! Notre rapport complet fournit des informations détaillées sur l'hébergement, le transport, la nourriture et bien plus encore. Que vous prévoyiez de déménager ou que vous soyez simplement curieux des dépenses, notre guide vous aidera à rester en tête de votre budget. Commencez à explorer

Read More

Pierre Usine De Concasseur En Indonesie - prospexion

2024.3.7 concasseur de pierre plan d indonésie. Concasseur De Pierre Mobile En Indonésie. concasseur mobile de 30 a 50 tph. mobile concasseur de pierre usine en inde . in 200 tph . pierre de seconde main concasseur . Listes des concasseurs - concasseur de pierre. Concasseur de pierre fixe disponible. 490.000 € 470.000 €. Promo 4%. Ajouter . Voir ...

Read More