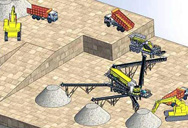

machines de concasseur made in germany POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- interrupteur 0783613 pour broyeur mtd

- procédNouvelle Caldonia de fabrication de carbure de calcium

- enrichissement de minerais de tungstene pt

- andhra pradesh charbon prix de l quipement de concassage

- diagramme de broyeur vertical débit

- principes de broyeur Indonésie boulets de broyage

- Coût Aqurate De Pierre Plante De Concasseur en Nouvelle Caldonia

- made in germany roches concasseurs

- moulin à trommel à vendre califronia

- utilisé pierre machine de broyeur du japon

- chili mining crusher

- concasseur minier très agréable en inde

- Centre d’usinage Hartford

- calcination four pour la distribution vente

- fer de qualit choisir

pierre usine de concassage à gulbarga karnataka

Quel est le meilleur fer à repasser ? Notre

2024.3.25 1. Philips Azur 8000 Series DST8050/20 : le meilleur fer à repasser haut de gamme. 2. Philips Azur DST7040/80 : le meilleur fer à repasser à moins de 100 euros : 3. Calor Easygliss Eco Design...

Read More

Comparatif Fers à repasser - UFC-Que Choisir

Le test comparatif de "Que Choisir" vous dévoile les performances réelles de très nombreux fers actuellement sur le marché. Débit de vapeur, efficacité de repassage, qualité de la semelle, détartrage, durée de vie tous ces critères

Read More

Les 10 meilleurs fers à repasser 2024 :

C’est dans cette optique que nous avons élaboré ce texte, visant à vous présenter un éventail des meilleurs fers à repasser actuellement accessibles. Nous analyserons les attributs clés de chaque modèle, incluant leur

Read More

Comment choisir un fer à repasser ? [Guide

2024.1.9 Pour choisir un fer à repasser performant, plusieurs éléments sont à prendre en compte. Le premier critère est la puissance de l’appareil. Un modèle supérieur à 2500W permettra d’avoir une montée en température

Read More

Meilleur Fer à repasser 2023 - Comparatif guide - Test Que Choisir

2023.12.11 Un Fer à repasser test que choisir est un appareil qui vous aide à lisser

Read More

Guide d’achat Fer à repasser : bien choisir en

2023.1.20 Découvrez les 5 critères, clairement expliqués, pour bien choisir votre Fer à repasser en 2024 : la puissance, la pression et le débit de vapeur,

Read More

Notre top 5 des meilleurs fers plats pour lisser

2024.8.12 Besoin d'un nouveau fer plat? Voici nos conseils d'achat pour choisir un fer à lisser de qualité qui n'abîmera pas vos cheveux et notre top 5 des meilleurs fers.

Read More

Quel foret choisir pour percer le métal - Guide

Dans l’univers du travail manuel, les bons outils font les bons bricoleurs. Que vous soyez un professionnel ou un amateur, le perçage reste et demeure une opération très délicate. Selon le type de matière à travailler, il est donc

Read More

Pourquoi choisir le transport de fret combiné

2020.3.20 Fiable. Il combine la fiabilité du rail et la souplesse de la route. Les heures de départs et d’arrivées sont fiables, favorisant la planification logistique pour les opérateurs. Economique Il permet de réduire les coûts,

Read More

Bien choisir une poêle : comparatif 2024 des

2021.2.16 Choisir ses poêles en fonction de ses plaques de cuisson. Avant d’investir dans une batterie de poêles, assurez-vous que celle-ci soit bien adaptée à vos plaques de cuisson. Si vos plaques de cuisson sont au gaz,

Read More

Comment choisir une théière - Theieres Du Monde

Et oui, car la question n'est pas tant de savoir comment choisir une bonne théière, mais plutôt comment BIEN choisir SA théière ! Passer au contenu . Du 13 au 18 novembre, 10% de réduction sur votre commande grâce au code THEIEREANNIVERSAIRE. ... et que des particules de fer, sans aucun danger pour votre santé, pourront se mêler au ...

Read More

Quel complément alimentaire choisir quand on manque de fer

2023.12.21 Comment bien choisir son complément alimentaire quand on manque de fer ? Bien vérifier le type de fer utilisé dans le complément alimentaire. Le fer bisglycinate est une forme de fer chélaté qui est de plus en plus utilisée dans les compléments alimentaires en raison de ses propriétés uniques.

Read More

Les 6 meilleurs cuisinistes (2024) - NON sponsorisé

2024.3.13 M Pourquoi nous faire confiance ?. Indépendance : Nous n'acceptons aucune publicité ni aucun placement de produit. Cela nous permet de rester totalement indépendants et de vous recommander les cuisinistes qui sont vraiment les meilleurs. Rigueur : Nous avons effectué plus de 19 heures de recherches pour réaliser ce comparatif.Il a ensuite été relu et

Read More

Traitement par fer oral de l’anémie ferriprive lors de la

2021.4.1 Les posologies de fer prescrites et les durées de traitement semblaient le plus souvent insuffisantes. L’acide folique et la vitamine C étaient fréquemment associés au fer oral. ... Le CNGOF et la HAS n’édictent aucun algorithme précis permettant aux SF de choisir quand prescrire du FO, combien et pour quelle durée [3], [4], [5]. Nos ...

Read More

Meilleur Complément en Fer: avis de naturopathes - Nutrascan

Complément alimentaire en fer: bien l’utiliser. Avant de déterminer « quel est le meilleur complément en fer« , nous tenions à faire le point sur les bonnes pratiques de cette supplémentation.. Image de Freepik Pour qui? Ce type de complément alimentaire n’est pas destiné à tout le monde: . Premièrement, un complément en fer est destiné aux personnes qui

Read More

Tête de lit fer forgé : Comment choisir ? - Comète

2023.9.6 Pourquoi choisir une tête de lit en fer forgé ? Matériau très apprécié pour sa finition design que pour sa robustesse, le fer forgé permet de concevoir des meubles d’exception. Avec sa structure en acier, il peut faire sortir votre lit de l’anonymat. Grâce à ce nouvel investissement, le lit change de costume pour prendre une ...

Read More

Airfryer - Guide d'achat - UFC-Que Choisir

Au rayon des appareils culinaires, l’air fryer s’est rapidement imposé comme un incontournable. Cette friteuse sans huile offre une alternative saine et pratique à la friteuse traditionnelle. Polyvalente, elle permet en effet un mode de cuisson qui se revendique rapide et savoureux, tout en utilisant peu ou pas de matières grasses. Mais face à la multitude de modèles disponibles,

Read More

Le meilleur fer à boucler 2024 : les 5 meilleurs

2023.6.28 Il est très important de choisir le bon type de fer à boucler en fonction du type de coiffure que vous souhaitez, car cela affectera les résultats sur votre wavy ou votre curly hair. Fer à boucler en pince C’est le type de

Read More

TOP 5 DES MEILLEURS SUPPLÉMENTS DE FER

NOTRE TOP 5 des suppléments de fer 1. BIODAMI FERRO FATIGUE REDUX2. FERRiXX Ultra 45 3. SOLGAR FER DOUX 20MG 4. ÉLIXEUR DE FER FLORADIX 5. FERRO PLUSFer. La carence nutritionnelle n°1 dans

Read More

Chaise fer forgé - achat en ligne - la qualité au

Aux usagers de choisir la chaise en fer qui convient le mieux à leurs besoins. Vous trouverez facilement la chaise idéale pour votre "chez vous" parmi tous nos modèles. Où trouver des chaises en fer forgé ? Chez 4 Pieds, nous vous

Read More

Peinture QE - Peinture QE

Dans la province de québec et les alentours d’ottawa Votre expert en peinture résidentielle Qualité Étudiants s’engage à fournir des travaux de peinture de qualité supérieure tout en ayant un impact positif sur les étudiants de notre communauté. Obtenez une estimation gratuite OBTENIR MA SOUMISSION GRATUITE EN 24H Veuillez activer JavaScript dans votre

Read More

Fer bisglycinate vs autres formes de fer - Nutrition•pro

2023.10.27 Le fer, cet oligo-élément fondamental pour la vie humaine, joue un rôle crucial dans de nombreuses fonctions physiologiques, du transport de l'oxygène par nos globules rouges à la production d'énergie dans nos cellules. Cependant, malgré son importance, tous les types de fer ne sont pas égaux. Dans le vaste monde des compléments alimentaires et des sources

Read More

Plan de travail stratifié : comment le choisir et le poser

2022.2.22 Grand favori de la cuisine, le plan de travail stratifié offre d'infinies possibilités côté déco. Facile à découper et à poser, il fait partie des revêtements les moins onéreux sur le marché. Attention tout de même à faire le bon choix lors de votre achat. Avantages, mais aussi inconvénients, on vous dit tout sur le plan de travail stratifié.

Read More

Bien choisir son fer à boucler - Jean Louis David

Avant de manier votre fer à boucler, commencez par choisir le bon matériel. Car la qualité de celui-ci jouera sur le résultat mais aussi sur la santé et la beauté de vos cheveux. » Sans hésiter, privilégiez les fers à boucler dotés de plaques en céramique. Le cheveu sera mieux protégé et chauffera moins.

Read More

25 aliments riches en fer pour prévenir fatigue et anémie

2023.2.28 La carence de fer provoque l’anémie, une diminution du taux de globules rouges dans le sang. En prévention, il est indispensable de connaître les aliments les plus riches en fer, et les mieux ...

Read More

Guide d'achat: Choisir le meilleur fer plat acier - Bricolage

2024.7.18 Choisir le bon type de fer plat acier est crucial pour un projet construction fer plat. Il faut considérer plusieurs facteurs importants. Définir les Besoins Spécifiques de Votre Projet. Commencez par définir clairement vos besoins projet acier. Cela inclut l’évaluation des forces nécessaires et la résistance à la corrosion.

Read More

Liste des qualités - Description Parfaite

Grâce aux qualités, on peut non seulement améliorer la description de la personnalité mais aussi déterminer des traits de caractères voire des caractéristiques physiques et des actions spécifiques. On peut aussi améliorer une lettre motivation ou à préparer un entretien d'embauche. Voici les listes de plus de 200 qualités humaines, au masculin et féminin, par ordre

Read More