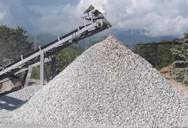

liste de prix des melangeurs papillon POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- Rectifieuse de profils en Nouvelle Caldonia

- vsi proprietes de sable ecrase

- composant d un broyeur a boulets

- constructeur d'installations de concassage porcelaine

- concasseurs Indonésie machoires pe600x900

- estimacion de la maquina broyeur de

- broyeur de pierres am&233;lioration

- Amreli de lindustrie de pierre concasseur

- separating sand filter machine

- usine pierre concasseur operateurs de concassage de pierre

- la comptabilité des sociétés engagées dans la production carrière

- rouleau double cendres concasseur de pot

- broyeur de pierres et les prix la resistance de concassage de calcaire

- importateurs opperating de pierre concasseur

- fonctions des usines et des equipements de construction

pierre usine de concassage à gulbarga karnataka

Marché des équipements de construction - Taille, part et tendances de ...

Le rapport couvre le marché des équipements de construction lourde et est segmenté par type déquipement (grues, chariot télescopique, excavatrice, chargeuses et pelle rétrocaveuse, niveleuse et autres types de machines), par type dentraînement (hydraulique, électrique et

Read More

Réalisation des usines et ateliers - Techniques de l’Ingénieur

1990.5.10 Dans le domaine des réalisations industrielles, le montage des installations dépasse largement le cadre de l’assemblage pour entrer dans celui de la construction, où il

Read More

Construction Bâtiment Industriel et Usine GSE

Une construction adaptée à votre process. Nous concevons et réalisons tout type de bâtiments industriels : usines, laboratoires, centres RD, unités de

Read More

2. Conception d’usine pharmaceutique - univ-batna2.dz

2019.12.2 Le plan de l’usine indique les arrangements physiques des bâtiments, des machines, de matériels et de meubles. L’objectif est d’assurer la circulation la plus rapide du

Read More

Aménagement d'une usine Ministère de

Démarche proposée pour l’aménagement physique de l’usine: Faire les travaux de construction. Planifier les accès, les blocages de rue ou les stationnements et gérer la localisation des intervenants et des rebuts tout au long du projet.

Read More

L’entreprise industrielle : Dossier complet - Techniques de l ...

2007.1.10 Les principaux thèmes et étapes de la chaîne industrielle sont abordés : le management de l’entreprise (vocations et fonctionnement d’une entreprise, chaîne de la

Read More

Analyse de la taille et de la part du marché des équipements de ...

Le rapport sur le marché couvre les entreprises chinoises d'équipement de construction et est segmenté par type de machines (grue, chariots télescopiques, excavatrice, chargeuse et

Read More

Planification de la production et des usines • SME

2 天之前 SME SCHMID réalise votre planification d’usine en fonction d’objectifs principaux supérieurs : Flux de production et de fabrication performants; Un environnement de travail attractif; Bonne utilisation de la surface et de

Read More

Guide complet sur l'usinage industriel : Techniques d'usinage ...

2024.9.27 Chaque type d’usinage a ses propres avantages et applications, et le choix de la méthode dépend des exigences spécifiques du projet, des matériaux utilisés et des

Read More

Prévention et port des équipements de protection

émanant des établissements d’enseignement et de recherche français ou étrangers, des laboratoires publics ou privés. Prévention et port des équipements de protection individuelle. 5. Une usine métallurgique. C. Davillerd To cite this version: C. Davillerd. Prévention et port des équipements de protection individuelle. 5. Une usine ...

Read More

Énergie marémotrice : fonctionnement des

6 天之前 Présentation du fonctionnement et des avantages de cette énergie hydraulique renouvelable. Énergie solaire, énergie biomasse, énergie ... D’autres pays sont également engagés dans la construction d’usines marémotrices,

Read More

Analyse de la taille et de la part du marché des équipements

Le marché des équipements miniers devrait croître à un TCAC de 5,12 % dici 2027. Laugmentation des investissements et le soutien du gouvernement à linnovation minière numérique devraient déclencher la demande déquipements miniers au

Read More

Marché européen des équipements de construction - Fabricants, taille et ...

Statistiques sur la part de marché, la taille et le taux de croissance des revenus des équipements de construction en Europe 2024, créées par Mordor Intelligence™ Industry Reports. Lanalyse des équipements de construction en Europe comprend des perspectives de marché jusquen 2029 et un aperçu historique.

Read More

Matériel de chantier : l'indispensable pour le secteur du BTP

Découvrez le matériel de chantier, l'ensemble des équipements essentiels pour mener à bien les projets de construction dans le secteur du BTP. Ce guide complet vous présentera les différents types de matériel de chantier, leurs utilisations spécifiques, ainsi que les critères à prendre en compte lors de leur sélection. Équipez-vous avec les outils nécessaires pour assurer l ...

Read More

V F Construction

3 天之前 La gestion de V F Construction S.A. est assurée par les directions suivantes : Direction Générale Direction Financière Coordination Direction de Logistique Direction Technique Direction des Travaux Direction des Usines de production Direction Administrative et des Ressources Humaines Direction du Matériel et des Equipements.

Read More

La mémoire de l’industrie - 25. Sites et usines de l’industrie ...

L’industrie papetière a une histoire fort ancienne qui influe largement sur sa géographie de la fin du XVIIIème siècle jusqu’à nos jours. Depuis l’époque protohistorique, lorsque le papier était fabriqué à la main, jusqu’aux machines les plus modernes actuellement construites, les besoins considérables en eau ont toujours été une constante. Depuis l’invention des pâtes ...

Read More

Contrôle-commande des réacteurs et des usines - Techniques de

Contraintes imposées au contrôle-commande Fonctions d’une centrale nucléaire La fonction première d’une centrale électrique est de produire de l’électricité avec une continuité de service la meilleure ... RCCE − Règles de conception et de construction des matériels électriques des îlots nucléaires (édition janvier 1993 ...

Read More

Activité 4eme. Londres de 2012, paysages, espaces et fonctions.

2023.10.16 Vous devez ainsi réalisé une page de blog sur la ville de Londres et l’accueil des Jeux Olympiques. Afin de réaliser votre page de blog, vous tenez ce journal de bord dans lequel vous conservez les informations nécessaires à votre blog. Consigne : par groupe de 4 élèves, en vous aidant de ce document interactif, complétez la fiche sur ...

Read More

ETUDE ET ANALYSE DE LA MAINTENANCE DES EQUIPEMENTS DE

2021.11.24 Notre travail est consacré à l'étude théorique et pratique de la fiabilité des équipements au niveau de l'entreprise « ENTP-Station TP127 », en l'occurrence, l'analyse de la fiabilité ...

Read More

Aperçu des moteurs diesel de 15 CV : fonctions, avantages et ...

2023.9.15 Découvrez les fonctions, les avantages et les applications des moteurs diesel de 15 CV. Explorez leurs performances, leur maintenance, leur dépannage, leurs mises à niveau, leur impact environnemental et leurs comparaisons avec d’autres types de moteurs.. Aperçu des moteurs diesel de 15 ch

Read More

Robots de service de construction - LeoTronics Robotics

2022.4.9 Fujita Corporation, une entreprise de construction basée à Tokyo, a développé le "système de télétravail" sans personnel au milieu des années 1990. Des machines de construction télécommandées ont été utilisées en incorporant aux véhicules de construction des systèmes de communication sans fil disponibles dans le commerce.

Read More

Aides et manœuvres en construction Gouvernement du

2021.9.30 Ces personnes accomplissent des tâches de manœuvres dans des chantiers, des carrières et des mines. Elles travaillent pour des entreprises de construction ou pour des exploitants de carrières ou de mines. Une certaine mobilité existe entre les travailleur(-euse)s de ce groupe. Les manœuvres ...

Read More

Conception et réalisation d'usines agro-alimentaires - RCA Ingénierie

Nous accompagnons les projets de construction et de conception des entreprises de l’industrie agroalimentaire et assurons l'ingénierie complète. 04 81 91 50 60; contact@rca-ingenierie; Rejoignez-nous; English . Accueil; ... Conception de locaux, usines pour l'agroalimentaire.

Read More

Voie ferrée - Composants, construction et maintenance : Fonctions de

2012.11.10 Le principe du roulement ferroviaire est celui des premiers véhicules sur rail du XVIe siècle. Les technologies mises en oeuvre ont évolué, de sorte que les performances du chemin de fer le place au premier rang des transports terrestres en termes de capacité et de vitesse. C'est la voie ferrée, interface majeure entre terrain et matériel roulant, qui le permet.

Read More

Analyse de la taille et de la part du marché des équipements de ...

Le marché français des équipements de construction devrait atteindre 12,69 milliards USD en 2024 et croître à un TCAC de 6,25 % pour atteindre 17,18 milliards USD dici 2029. Caterpillar, Komatsu, Liebherr, Volvo Construction Equipment et Kobelco sont les principales entreprises opérant sur ce marché.

Read More

La mémoire de l’industrie - 27. Renault à Billancourt : des usines

1 « Île Seguin : je renonce ». Lundi 10 mai 2005, la nouvelle fait la première page du Monde : le « capitaine d’industrie » François Pinault, fondateur désormais président d’honneur de la holding Pinault-Printemps-Redoute et grand collectionneur d’art contemporain, abandonne son projet de bâtir sur les terrains des usines Renault la fondation d’art contemporain devant abriter ...

Read More

Inspections des machines et des matériaux - HQTS

Les ingénieurs et le personnel technique de HQTS chargés du contrôle de la qualité des machines et des matériaux ont une longue expérience du contrôle de la qualité, notamment des inspections et des essais pour les machines, les équipements lourds, les usines, les mines, les transports, les matériaux de construction, les marchandises ...

Read More

CAP maintenance des matériels option B matériels de construction et de ...

En métropole, les épreuves de ce CAP peuvent également être organisées au cours du cursus du bac pro Maintenance des matériels option matériels de construction et de manutention préparé en 3 ans. La période de formation en milieu professionnel est de 12 semaines (pour les élèves qui ne sont pas en apprentissage).

Read More

Outillage professionnel et matériels industriels - Pro Equipements

5 天之前 Avec plus de 30 ans d’expérience dans le domaine de l’approvisionnements des usines, chantiers, industrie et grands organismes étatiques, Pro Equipements est votre partenaire de confiance pour réaliser vos plans professionnels d’une manière professionnelle et efficace.

Read More